The new design for Famot Pleszew

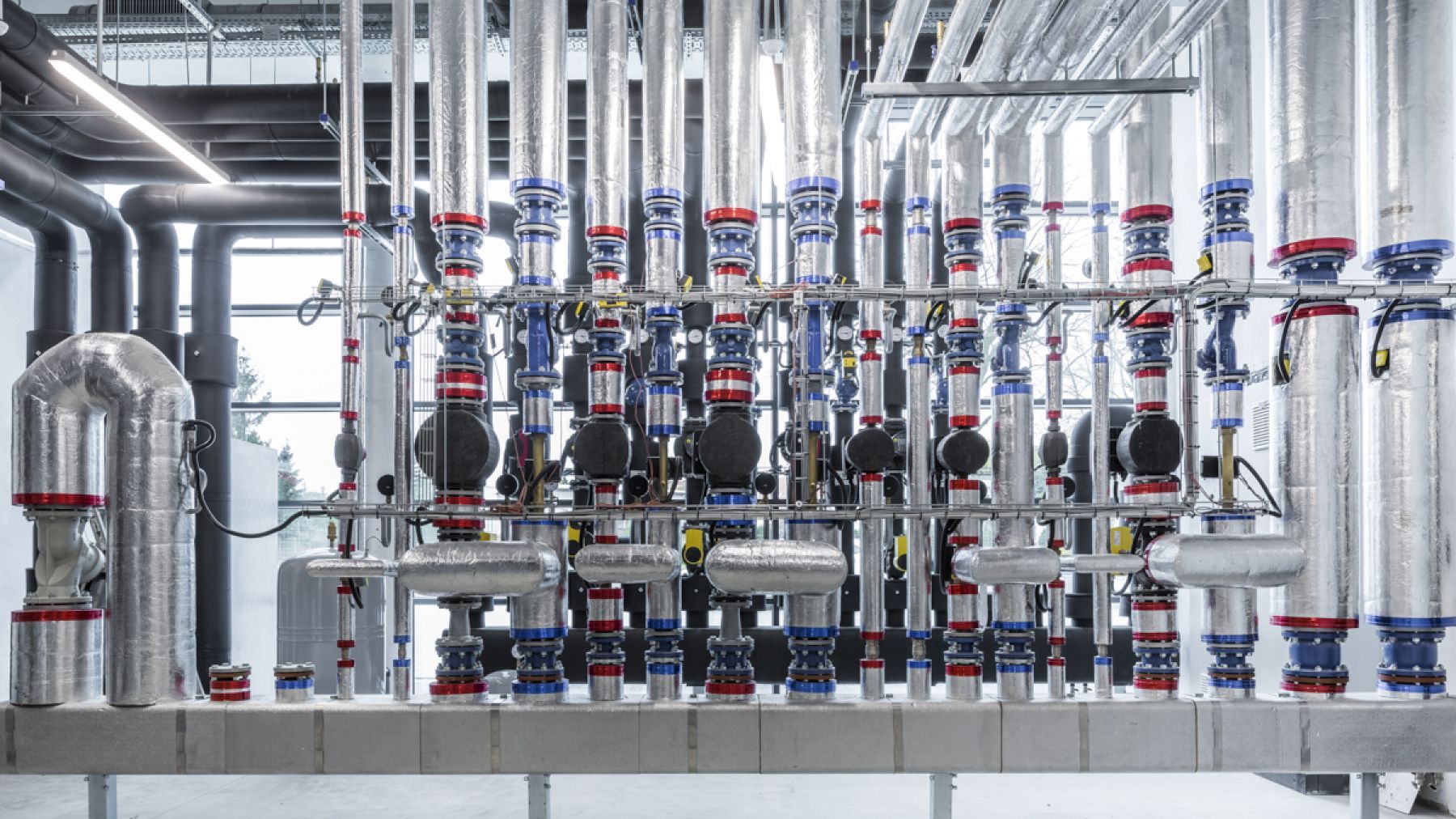

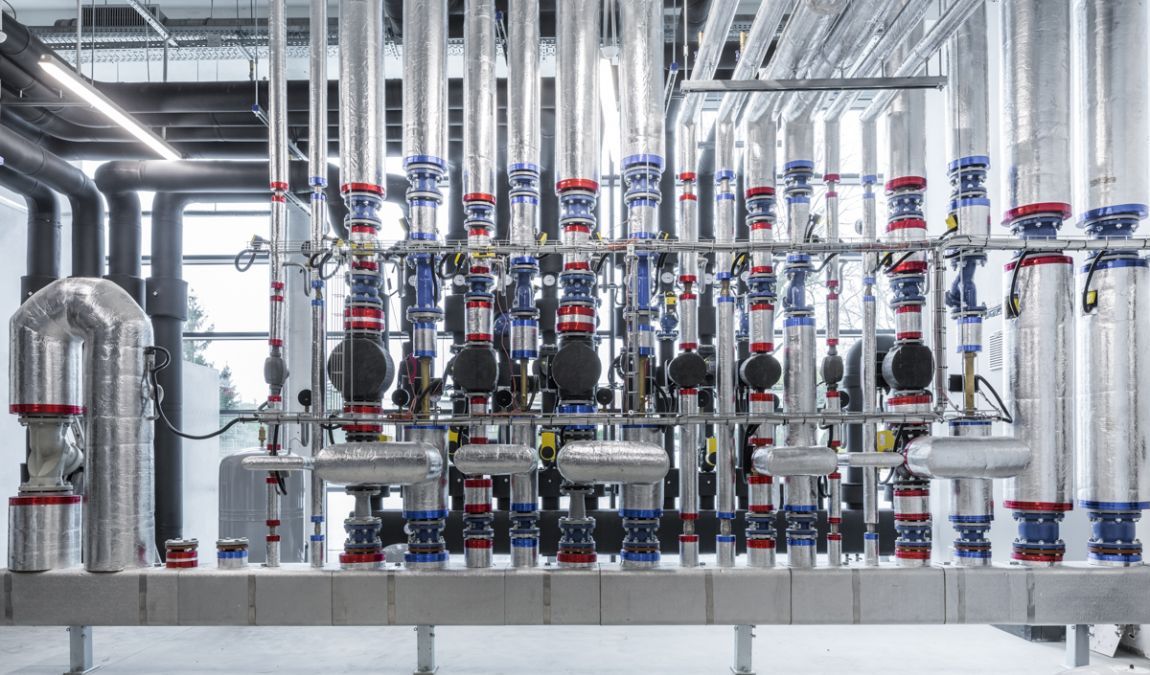

The subject of the investment is the expansion and modernisation of the building in which the technological and production boiler house, oil warehouse, transformer station and MV switching station are located. The building was completely reconstructed and at the same time the continuity of production operations in the plant was maintained. The provision of the temporary compressed air system as well as the process heat system enabled the comprehensive modernisation that is safe for the production process and the construction crews. Owing to the modernisation, the boiler house power increased by 1MW, which in total gave the power equal to 3MW. Also 4 modern 400 kW compressors, including the heat recovery system were installed. The boiler house was also provided with a 250 kW CHP block, which resulted in the reduction in operational costs and contributed to an increase in the energy safety related to the machinery power supply. Owing to a buffer tank and an absorption unit, the excess of heat generated during the summer season will be converted into the refrigerating system as part of the trigeneration system. Energy safety for such precise machines manufactured at Famot Pleszew is a key issue, therefore, during the modernisation of the boiler house, also the power system was reconstructed by adding an extra 2000 kVA transformer.

The subject of the investment is the expansion and modernisation of the building in which the technological and production boiler house, oil warehouse, transformer station and MV switching station are located. The building was completely reconstructed and at the same time the continuity of production operations in the plant was maintained. The provision of the temporary compressed air system as well as the process heat system enabled the comprehensive modernisation that is safe for the production process and the construction crews. Owing to the modernisation, the boiler house power increased by 1MW, which in total gave the power equal to 3MW. Also 4 modern 400 kW compressors, including the heat recovery system were installed. The boiler house was also provided with a 250 kW CHP block, which resulted in the reduction in operational costs and contributed to an increase in the energy safety related to the machinery power supply. Owing to a buffer tank and an absorption unit, the excess of heat generated during the summer season will be converted into the refrigerating system as part of the trigeneration system. Energy safety for such precise machines manufactured at Famot Pleszew is a key issue, therefore, during the modernisation of the boiler house, also the power system was reconstructed by adding an extra 2000 kVA transformer.

Back

Back